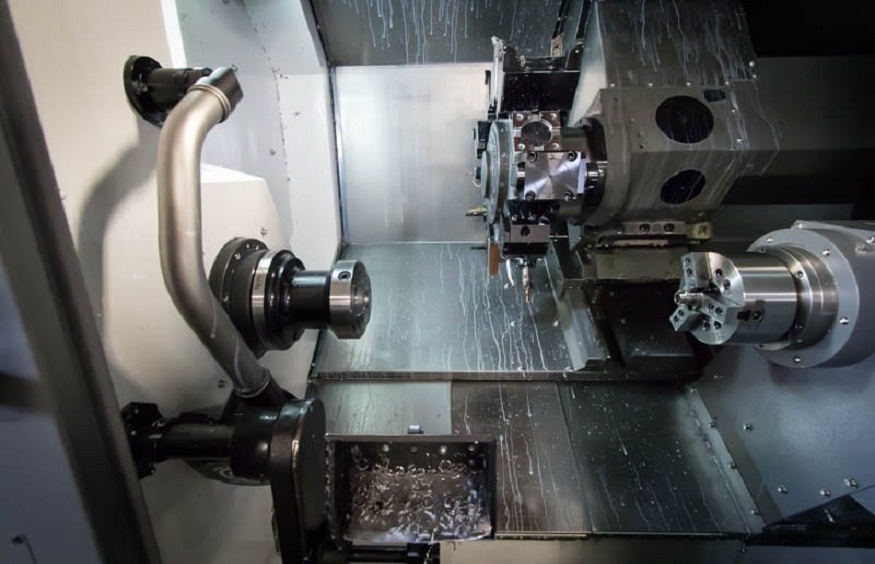

With the advent of CNC lathe machines and contemporary cutting equipment instruments, the industrial sector has experienced tremendous developments. Production procedures have undergone a revolutionary transformation, becoming more accurate and efficient than ever thanks to technological advancements. The incorporation of CNC lathe machines and cutting equipment tools has improved product quality and productivity, among other benefits for industrial operations.

Improvements in Accuracy and Precision

The remarkable precision that cutting tools and CNC lathe machines provide is one of the main advantages of employing them. Conventional hand machining techniques frequently led to variances and irregularities in the items that were produced. On the other hand, producers can consistently make identical components and reach extraordinarily tight tolerances using contemporary cutting equipment. The precise motions of CNC lathe machines are made possible by computer-controlled systems, which guarantee that every cut, turn, or drill operation is carried out precisely as intended. Because of its great accuracy, less waste is produced, mistakes are made less frequently, and precise specifications are met by the finished goods.

Higher Output and Effectiveness

The use of CNC lathe machines and cutting equipment has significantly increased production speeds. With little assistance from humans, these devices can run constantly for long periods. In contrast to manual operations that rely on the ability and endurance of the operator, CNC lathe machines can work continuously and maintain constant output levels throughout production runs. The time required to finish each part is decreased by the faster material removal rates made possible by advanced cutting machine tools. Higher production volumes and shorter lead times for clients are the results of this enhanced efficiency.

Cutting Manufacturing Costs

Cutting tools and CNC lathe machines need a substantial initial investment, but over time, they save a lot of money. Because fewer humans are required to control production, the automation of these machines lowers labour expenses. Additionally, cutting equipment’s precision reduces material waste and maximises the utilisation of raw materials. To optimise return on investment, CNC lathe machines can also run with less supervision in the evenings and on the weekends. Because fewer resources are required to produce new parts or rectify errors, the decrease in errors and rework also results in cost savings.

Better Safety Requirements

Numerous safety mechanisms built into CNC lathe machines and other modern cutting tools shield operators from potential dangers. Protective enclosures, emergency stop buttons, and automated shutdown mechanisms that kick off when problems are identified are frequently seen on these equipment. Operators may oversee the cutting process from a safe distance thanks to the automated nature of CNC lathe machine, which lowers their risk of being cut by sharp objects, struck by flying debris, and other workplace hazards. This improved safety lowers downtime and accident-related expenses in addition to safeguarding workers.

Adaptability in Production Activities

Manufacturers can produce a wide range of parts and components due to the versatility of CNC lathe machines and cutting equipment tools. Fast transitions between product lines are possible with these machines thanks to their quick reprogramming capabilities, which eliminate the need for significant retooling. The options for product development are increased by the fact that modern cutting equipment tools can deal with a wide range of materials, including plastics and metals. Since CNC lathe machines are so versatile, fewer specialist pieces of equipment are needed because many operations may be completed on a single machine.

Outstanding Surface Polishing

The final goods’ quality has grown dramatically with the use of CNC lathe machines and cutting tools. Excellent surface finishes that frequently require no further processing can be produced by these devices. All of the components produced have smooth, uniform surfaces thanks to the constant cutting speeds and feeds that CNC lathe machines maintain. When used correctly, high-quality cutting tools may create parts with exceptional usefulness and appearance. Enhancing the surface finish of products can lead to improved performance and longevity in addition to improving their look.

Decreased Human Error

Cutting tools and CNC lathe machines drastically lower the possibility of human error throughout the manufacturing process by automating it. These machines will generate identical parts without fail as long as they are programmed appropriately. This constancy is especially useful for intricate parts that need to be precisely operated on several times. Reducing human error not only lowers costs connected with defective items but also boosts customer satisfaction and product quality.

Gathering and Analysing Data

Sensors and monitoring systems that gather useful production data are frequently installed on modern cutting tools and CNC lathe machines. Analyzing this data can help to anticipate maintenance requirements, improve manufacturing procedures, and spot any problems before they result in downtime. Manufacturers can increase efficiency and quality by using data to inform their decisions by tracking and measuring a variety of metrics during the production process. Maintaining constant quality standards across manufacturing runs is another benefit of this thorough monitoring.

Benefits to the Environment

Sustainable manufacturing methods are facilitated by the accuracy and productivity of CNC lathe machines and cutting equipment. These devices reduce material waste by using precise operations and well-designed cutting routes. Less energy is lost in making defective parts due to the decrease in mistakes and rework. Energy-efficient features are another common component of contemporary devices, which lowers power consumption when they are in use. Components can be developed to use the fewest materials possible while preserving the essential strength and functionality thanks to the ability to manufacture parts to exact specifications.

Durability over Time

Cutting tools and CNC lathe machines operate dependably for lengthy periods when maintained properly. These devices, which frequently have sturdy construction and premium parts, are designed to survive the demands of continuous use. Production schedules may be precisely planned and managed because of the equipment’s consistency and dependability. Frequent maintenance improves the precision and lifespan of cutting machine tools, giving manufacturers a higher return on their investment.

Conclusion

The use of CNC lathe machines and cutting equipment tools has revolutionised the industrial industry and brought about a host of advantages beyond basic automation. These technological developments continue to spur innovation in industrial processes, from increased productivity and precision to increased safety and sustainability. Cutting tools and CNC lathe machines will certainly become more capable as technology advances, giving the manufacturing sector even more benefits. Purchasing these technologies is a commitment to modern manufacturing operations’ competitive edge, efficiency, and quality.